|

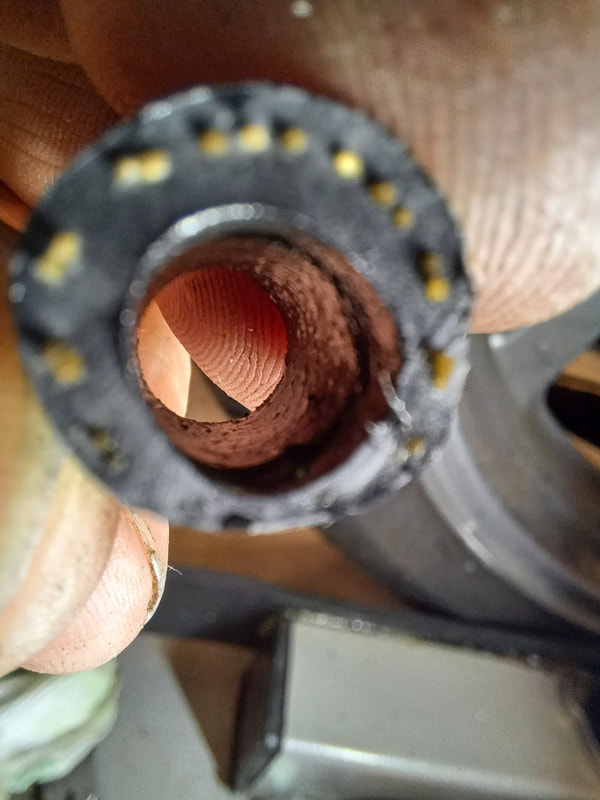

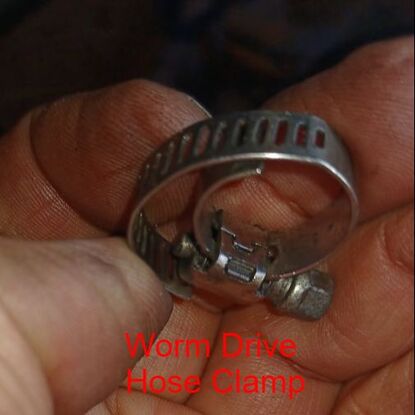

Just finished a water pump job. Everything is clean and tight. Got the radiator full, topped up the overflow tank, fired her up, watched for coolant flow when the thermostat opened, put the radiator cap on nice and snug, and… DANG…there is a leak…one stinking, little, slow drip…on the smallest hose in the system. WTF. There it is. Right under the hose clamp. How is that possible? Well…here’s how. The end of the hose is nice and round and thick…like the rest of the hose. But, uh oh, look at where the clamp has been on the hose. Yep…there’s the hole; right under the lead screw housing. Cutting off the hose end affords an even more telling look. The hose was completely distorted. The flat bottom of the worm drive housing squashed the life out of that poor little hose…squashed a hole right through it. Oh yea…the smallest hose in the system needed a better small hose clamp; one that does not have a flat spot in the clamping surface like the one on this worm drive hose clamp that had been used on this hose. Here’s one option…a fuel injection hose clamp.

Note how the clamp is designed to deliver clamping force uniformly around a small hose. Make no mistake, even these clamps can be applied in a way that causes a pinch right there under the screw. (Don’t ask me how I know that.) The trick is to get the metal clamp to slide smoothly around the hose as it is being tightened. How? There is a magic rubber dressing that can be used to gigantic advantage every place rubber comes into contact with metal and needs to move, rather than stick. It is awesome for sliding stubborn hoses onto or off of water pump or radiator fittings, it is the bomb for demounting and mounting tires (that’s right…dump the soapy water…this stuff will change your life), it is the coolest for slipping wires through jackets. What is this magic stuff? It is already on your work bench; plain old WD-40. That’s right. It works miracles on rubber when you need to get it to slide past some metal…and then it evaporates away, leaving newly mounted tires or hoses or hose clamps, clean, dry, and ready to go to work. So, yea, this is a twofer. First, you learned NOT to use ordinary worm drive hose clamps on any hose where the flat spot in the worm drive mechanism represents a significant portion of the circumferences of the hose to be clamped (i.e. a too small hose). If you do, you risk putting a flat spot in your hose…and causing a leak. Second, you learned that, when it comes to fitting rubber parts, WD-40 is your best friend. Comments are closed.

|

Categories

All

Archives

January 2024

|

|

© WrenchMonster 2018

|

WrenchMonster™ is a Division of DemonLite, LLC.

|

RSS Feed

RSS Feed