|

Introducing STella This is STella, a 2007 Honda ST1300 PanEuropean. She has been with me since 2010, acquired from the original owner with less than 2000 miles on the odometer and already heavily upgraded. He gave her a Hondaline OEM top box, shipped from Europe at absurd expense (because Honda simply will not sell one in the US, even as a repair part, presumably because they didn't want the ST1300 to cut into Gold Wing sales). He put a Sargent seat on her, add-on fork flood lights, additional HyperLite LED tail lights, and unfortunately for him, a gigantic windscreen made by Rifle; which, it turns out, was the reason I was able to get STella from him. The first day out on the freeway, she nearly threw me off. At 70 mph she was suddenly almost uncontrollable. The front tire was trying to lift off the pavement. The giant Rifle windscreen was making such tremendous vacuum above the handle bars, the front end was being pulled upwards almost lifting the front tire off the ground. It scared me...and clearly it had scared him, so he just didn't ride her. I did a little research, found a high-tech, wind tunnel-designed, AeroFlow windshield for her. Like the ST riders who had already put one on their bikes, found that I could now easily run her up to 110 mph and she was now solid as a rock. (They say she can hit 155, but I haven't tried it!) With that problem solved, a series of upgrades followed that turned STella from a great touring bike into a fantastic touring bike. (She got an AeroFlow headlight shield at the same time, so her headlight is still showroom fresh.) The next major personality change was a set of Gen 3 Helibars, that raised and moved the grips much closer to the rider, eliminating the tiresome problem of having the rider's weight resting on his palms like you would on a sport bike. On the first day ride with the Helibars, I knew STella and I were now a match made in heaven. Then both grips got Throttle Boss palm rests added, eliminating the usual strain on the web between thumb-forefinger wrapped around the grips. Next she got Throttle Meister throttle lock / bar end weights that enables highway cruising with the rider's right hand in his lap. She got huge PIAA driving lights on powder coated billet aluminum mounts, and all the bulbs in the headlights, flood lights, and the driving lights were upgraded to PIAA's 2x bulbs. They produce 2x the light for their electrical wattage...so the high beams, for example produce 140 watts of light each, but each consume only 70 watts of power. The flood bulbs consume 35 watts but each produce 70 watts of light and the driving lights are also 140/70 units. STella makes her own daylight now. She got a Stebel 140 db air horn that hurts if you don' t have your helmet on, along with an additional horn relay that not only sounds both the stock horns and the Stebel horn all at once, when you hit the horn button, it also lights up every light on the front of the bike, whether they are otherwise turned on or not. Honking the horn button is to invoke sunrise. She got modulators on the headlights and flood lights that can be activated or deactivated in any combination with a bank of switches mounted in a neat row under the speedo cowling. If you have never ridden with headlight modulators, try them soon. You will never go back. Drivers don't just notice you...they dodge to get out of your way. In addition, a tricky switch was added that allows the headlights to be locked on High Beam while the handle bar dimmer switch activates and deactivates the driving lights, perfect for those late night runs on divided Interstates (don't use them that way on non-divided highway). She got a amber Zenon strobe light on her tail with a custom controller that shuts down the strobe any time a brake light or turn signal lights up...and automatically turns it back on 10 seconds after the last brake or signal light goes off. Numerous times drivers have pulled up and thanked me for that strobe light. (One guy caught up with me in an east Texas gas station about midnight one night after I had been parked there over ten minutes for a gas and bathroom stop. He said he had been watching me crest the rolling hills from over ten miles behind me for more than an hour.) Those happy drivers all said they loved being able to easily spot STella out in front of them, day or night. And speaking of turn signals, she got and auto-canceler installed so you will never ride down the street with a blinker stuck on because you got distracted and forgot to turn it off. She got a slick set of hideaway Highway Blades (fold out highway foot pegs) and some massive tip-over bars (that proved their worth when she got knocked over when a car backed into her while parked, and the saddle bags didn't even get a scratch). She got a FendaExtenda (an add-on lower lip for the front fender) that helps keep rocks and other road debris from hitting the radiator. She got a smart EarthX brand Lithium battery (which has a native voltage of over 13V so it REALLY spins the starter with authority), and the specialized battery tender designed specifically to manage lithium smart batteries, as well as a custom volt meter / amp meter so you can see how your electrical system is doing at a glance as you ride. She got a tire pressure monitoring system that keep you constantly updated on the current pressure and temperature of each tire that sounds an alarm if they go out of spec. And those tires, always top line Michelins, are always balanced with Ride-On balance / sealant gel, substantially reducing the chances of a flat in the middle of a trip. She has nylon straps secured to the frame, tucked away under the seat, perfect for tying down big duffle bags full of camping gear for those long cross country trips...as well as five separate RAM ball mounts and four separate 12 V accessory outlets to run any phone, GPS, radar detector, radio, or heated clothing any rider could possibly want. To top that all off, she has powerful grip heaters that keep the rider warm even when temps drop into the 30's. While under my care she has had countless oil changes (Castrol synthetic), Iridium NGK spark plugs, synthetic brake & clutch fluid changes, coolant changes, final drive oil changes, K&N air filter changes, tire changes, new fork seals and oil, EBC brake pad changes, and every other normal maintenance item the book requires. In addition she has gotten a new alternator, fuel pump, ignition coils & wires...and less than 50 miles ago, a complete new clutch (despite being only 25% worn from new), water pump (which was not leaking), instrument cluster, and a full set of front wheel, rear wheel and rear hub bearings, a new windshield drive mechanism (electrically raises and lowers the windshield with a thumb button), and a brand spanking new AeroFlow windscreen,…plus all new fluids. She still has her original owner's manual and the Honda Factory Service Manual...as well as a complete record of every service and every part replaced. Here maintenance log can be seen here. Magic on Two Wheels

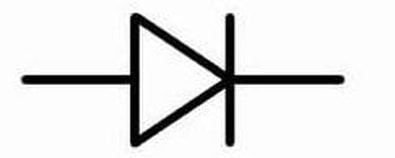

STella is incredibly capable and very well traveled. She has run up the backbone of the Rockies all the way to Wyoming, into Seattle, down through Oregon, Idaho and Utah. She has been to Chicago several times while meandering through the Ozarks. She has crossed the Mississippi and the Ohio repeatedly, memorably at the St Louis Arch. She has run the Blue Ridge Parkway and the Mississippi Delta. She has made weekend trips into the mountains of New Mexico and knows the Twisted Sisters by heart. Her top box and saddle bags giver her more luggage space than a Gold Wing. She even has a color matched high capacity magnetic tank bag that adds even more space. She is among the most quiet bikes on the road. Flying down the highway at 80, sitting in a still air bubble behind the AeroFlow windscreen, about all you hear is the wind rushing by. If you want to go farther, faster, more comfortably than just about anybody else on the road, STella is the way to go. So why are STella and I parting company? It is not easy to say, but she needs a younger man. She has been my faithful companion for over 12 years... but I have not aged as well as she has. There is simply no way around the fact that when STella is stopped, she is heavy. Once she starts rolling, the weight disappears, but when it is time to put a foot down, it becomes clear that all that magic does not come for free. Tipping the scales at about 750 lbs. dry, her big 125 hp V-4, her two-level 7.5 gallon tank, full saddle bags and top box, all combine to make it clear she requires an experienced rider and constant vigilance to keep her upright. It is not difficult, but inattention is quickly punished. And if she starts to tip, she needs a rider with some manly muscles to keep her in check...and the simple truth is that at 67, mine are starting to fade. We need to go our separate ways before I hurt her. STella has been 77,000 wonderful, adventurous, beautiful miles with me...and is perfectly capable of going more twice that far, as many ST1300's have, if she continues to get the careful maintenance she has had. She is going to meet some guy in his 40's or 50's who is ready to go chase some sunsets for another ten or twenty years with her...and she is gong to make him very happy. With a little luck, I will get to continue to be her favorite mechanic as she continues her journey. I had never heard of a Honda Ascot when the tow truck dropped this little gem on the driveway. It was, in the early 80's, an absolute technology showcase in a mid-size package. She has a 6-speed transmission, shaft drive, mag wheels, liquid cooling, studs on the rear fame members designed to hang detachable hard bags, and even a warning light on the dash to tell you if your tail light has burned out! Remarkably, they didn't sell worth a darn and were produced only two years. In the end, Honda dealers flushed these bikes onto the market at fire-sale prices. Their only real problem seemed to be that the gas tank was a little to small for a bike that would have made a great lightweight touring bike. Look them up. The more you read about the VT500 Ascot, the more impressed you will be. If you find one as nice as this one, buy it for a song and ride it for the rest of your life. As you can see, this one came in very neglected, but not abused. She had spent too much time sitting lonely in a shed. So naturally the carbs were fouled, the battery was toast, the brake fluid was bad, and she needed an oil change. But what was particularly interesting about this job, was that she was on her way to being in a movie...and needed to run right and right away. Being a Honda, parts were easy to get and with the normal Make-Run project ministrations, she was ready to go right on schedule...but when it came time to change her four spark plugs (two per cylinder), she showed herself to be a true Honda V-Twin. I cannot figure out why so many Honda V-Twins are like this, but I see it over and over, across lots of different models they have made. It is such an odd quirk for a company that usually does everything nearly perfectly, I have just got to tell you about it. On lots of their V-Twins, Honda makes it absurdly difficult to change the front left spark plug. Is this a big deal? No, not really. But it can be really aggravating if you don't have the right spark plug socket. And I have seen a number of bikes come in that have clearly had all of their other plugs changed at some point, but the front left plug has never been changed. Some mechanics just skip it, rather than deal with getting the plug out. That is really crummy. So the message here is, if you have a Honda V-Twin, make sure your mechanic is willing to do the job right. (I guess that is good advice, whatever bike you may have!) You may notice that the photo of the long, thin spark plug socket shows lots of scratch marks on the outside. That is because on some bikes, even this special tool was too thick to fit down the hole. So naturally, I took it over to the bench grinder and ground it even thinner! Sheesh! Well, it all worked out fine in the end, and out little hero got a nice bath and made it to the set on time. The script says the rider finds a dead body in the woods. Who did it? Was it Major Mustard with a wrench? How do you know if your battery charging system is working? Check your battery voltage with the bike turned off. Start the bike. Check the battery voltage with the bike running at 1500 RPM or more. The battery voltage should now be higher that it was...and ought to be somewhere between 13V and 15V. If it is not, and particularly if your battery voltage is LOWER than it was with the bike turned off, your charging system has taken a powder. Now you need to figure out what is wrong with it.  Typical Motorcycle Stator Typical Motorcycle Stator One fun thing about motorcycles is that the charging system (which you would just call "the alternator" on your car) is broken into its two major components, so you can look at them (and repair them) independently. The first part, the Stator (so named, I think, because it STAYS still while magnets spin around it) is simply (usually) three coils of wire that are located very near one or more magnets attached to the engine, so that when it is running, the magnets spin by the coils, inducing an electric current within them. (Yes, Virginia, that is how almost all the electricity you have ever used is made. Coils of wire are passed through a field of magnetic flux, causing the electrons within the wire to get excited and go flying off to some atoms further down the wire that are not quite so excited.) As you can see in this photo, the three coils are artfully arranged so that you would be unlikely to guess that there are three of them, but we know there are three and only three because there are three yellow (typically yellow) wires connected to the lot of them. How that works out will become clearer as we move on... The second part (Have you already forgotten there is a second part? I would have.) is the Regulator. The Regulator, as you might well imagine, regulates the voltage produced by the Stator. Because they are attached to the engine and the engine runs at wildly variable speeds, the magnets induce wildly variable current in the Stator, which is seen as wildly variable voltages on the output connector of the Stator (the three yellow wires). What is worse is that the Stator is producing AC current (alternating current) while your motorcycle, and notably your motorcycle battery, operates on DC current (direct [unidirectional] current). So when we call that second part of the charging system "the Regulator" it is shorthand for what it really is, which is a Rectifier-Regulator. What is a Rectifier? It is something that fixes (rectifies) something else. In this case, the "fix" is that it prevents electricity from flowing backwards. It converts AC current into DC current. In most cases, it is desirable to make use of both the forward and backward energy a Stator provides. When this is done, the circuit that routes Positive and Negative (forward and backward) current flow, so both get sent out in the forward direction, is called a "full-wave" Rectifier. And that is what is being done inside most motorcycle Regulators (a.k.a. Rectifier-Regulators). Just to make matters a little more confusing, when someone says "Rectifier" they may be referring to the entire gizmo that plugs into the bike, or they may be talking about a single-junction semiconductor device with two wires on it. Although the antiquated term for such a device may be "rectifier", for clarity, such a device is usually called a diode. And a module that accomplishes rectification, which is built using a number of diodes, may be called a Rectifier. The schematic symbol for a diode is shown below. The message in the image is very literal. A diode allows current to flow in the direction the arrow (the triangle) is pointing, and the wall (the vertical line) blocks current that might try to come in from the right. If you went out and bought one diode off the shelf, it might look a lot like the cylinder with the white stripe shown below. The white stripe corresponds to the vertical bar in the symbol drawing. It shows where current cannot enter the diode. The several diodes in a Rectifier-Regulator convert the AC current produced by the Stator into DC current...but by themselves do nothing to make sure that the very high voltages produced by the Stator when the engine is at high RPM, voltages that can exceed 75 volts AC, do not fry the electronics on your bike or fry your "12 volt" battery. That job is handled by the other half of the Rectifier-Regulator (often simply described as "the Regulator"). Exactly how voltage regulation is done is beyond the scope of this post, and it may be done is several different ways, depending on the preferences of the folks who designed the charging system, but in the end, the Regulator will prevent the net DC voltage seen by your battery to be no more than about 15 volts. Typically "charging voltage", the voltage seen across the battery terminals while the engine is at 1500 RPM or more, is going to be around 13.5V to 14.5V DC. That is enough to make sure that current flows INTO the battery, rather than out of the battery (charging, rather than discharging). A good, ordinary lead-acid battery will show about 12.4V to 12.6V DC when it is charged and resting, so hooking a battery to a voltage source that is higher than that will charge the battery. A Typical Charging System Schematic This is a circuit diagram of a typical motorcycle charging system. The lines in the drawing are wires and when you see a round dot printed on top of the intersection of two lines, two wires, you know that those two wires are connected to each other. (Line crossings without a dot do not represent an electrical connection.) You can also see six diodes inside the Regulator-Rectifier module. The Stator is show as three coils of wire on the left side of the drawing. One end of each coil is connected to another coil and the loose ends are connected to the diodes in the Regulator. FYI - On many bikes, the three wires that run from the Stator to the Rectifier-Regulator (a.k.a the Regulator) are bright yellow. Notice that each coil of wire in the Stator is connected to a dot between two diodes. Notice that the diodes are all pointed UP, showing that all the current flows toward the positive (+) connection of the battery...and on to other components of the bike via the main fuse and the main power contacts in the ignition switch. Notice that each wire from the Stator is connected between two stacked diodes, so that each pair of diodes does "full-wave rectification" of the current coming from each coil (each "phase") of the Stator. The three coils of the Stator and the three pairs of diodes shown, along with the voltage regulating mechanism depicted by a regulator box and three switches (which are actually some transistors and other stuff) are the essential elements of what is known collectively as a "Three-Phase Charging System". WHEN THINGS GO WRONG There are three main functions in the charging system; production of electrical current by the Stator, rectification of the current by the diodes, and regulation of the voltage by the regulator circuits. Any of these three sections can fail or all of them can fail...and they can fail open (fail by disconnecting) or they can fail short (they can pass current to an unregulated degree or along an unsuitable path).

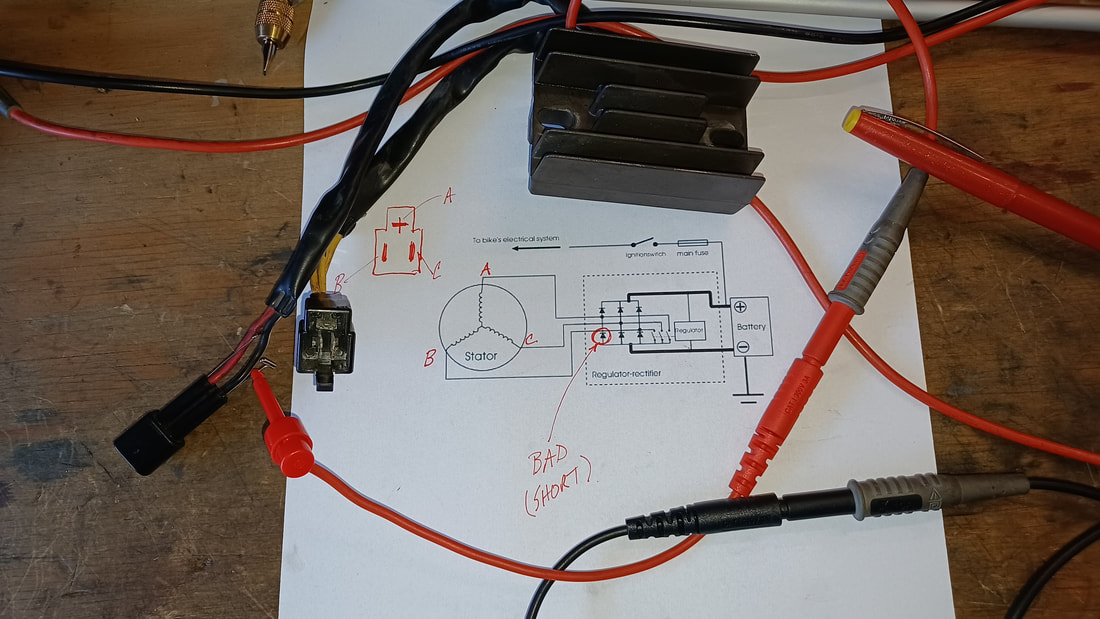

Testing the Stator coils is very easy. Unplug the Stator from the bike and measure the resistances between the three yellow wires...and between each yellow wire and the frame of the bike. There should be NO current flow from any Stator connection and the bike frame (a.k.a. Ground), and the resistance seen between any two of the three Stator wires should be roughly equivalent...and pretty darn low...probably near 1 ohm. (But whatever DC coil resistance may be, the main concern is that they be about equal, say within 10% - 20% of each other.) If any Stator lead is shorted to ground (to the bike frame) the Stator is bad. If any two Stator leads show a dead short (~zero ohms) or leaks to the bike frame, the Stator is bad. Testing the diodes in the Regulator-Rectifier is more complex conceptually, but not in practice. The Regulator needs to be unplugged from the bike completely. The DC wires (often red and black) and the AC wires (usually three yellow wires) need to be disconnected from the bike's wiring harness. Then each phase can be tested. Sidebar: A Multimeter with a Diode Test Function I use a very nifty multi-meter (that was not at all expensive) with some very useful functions, including Diode Test Mode. Note in these photos that the control knob is set to measure resistance but the meter is reading volts (!). That is because the way a multi-meter always test resistance is to send out a know voltage from inside the meter and then look at what comes back. Diodes have a very particular characteristic compared to other devices like resistors and light bulbs. While resistive devices will show a larger and larger voltage drop across their terminals as voltage is increased, the voltage drop across a diode will stay nearly constant, despite the fact the diode is conducting more and more current flow as the applied voltage increases. In Diode Test mode, the meter reports the voltage drop it is seeing across the device being tested.

Regulator Diode Testing Connect your diode tester to a Stator wire and check for diode current flow through the positive and then the negative terminals of the DC output voltage connector. One of the DC terminals should show current flow...only one. Then reverse your diode tester connections and check the same points. Now the OTHER DC terminal should show diode current flow while the one that flowed before should indicate blocked flow.

In the example shown here, current was found to be flowing from terminal A on the Stator to the positive (+) DC terminal of the Regulator (which it should) AND to the negative (-) DC terminal of the Regulator (which it should not). That measurement proved that this was a bad regulator. It must be noted that testing the diodes in this manner CANNOT conclusively prove a Regulator is good. Such a test can only prove that a Rectifier part of the Regulator is bad. The diodes could all be just fine and the regulating circuits themselves could be bad, resulting in bad system voltage on the bike. However, in this case, testing revealed at least one bad diode inside the Regulator assembly, so it is a gonner. Additional Tests

Once you have determined the major components of the charging system are functioning with the bike turned off, there are other tests you can do with the bike is running. With the engine running AND the Stator unplugged from the regulator, check AC voltage between each of the three Stator output terminals (Three measurements...on the drawing above would be point A to B, A to C, and B to C). The voltage seen at any given engine RPM should be about the same for each measurement (because the coils and magnets are the same for each phase). You may see nearly 100V AC on these terminals, so be careful. Anything much past 24 volts can be noticeable and 48V and up can hurt...and can certainly be deadly. Watch yourself. This test is particularly useful if the Stator is wounded and only shows a short at higher voltages or only shows an open when it is being vibrated by the motor. The key for each of these measurements is that under the same conditions, they should match each other pretty closely (say +/- 10%). Needless to say, if you see bad results in these tests, you have a bad Stator and need a new one. Repeat the measurement of the AC terminals with the Regulator plugged in. Again, each phase should be the same as another...although probably not the same voltages seen when the Stator was unplugged. Seeing generally lower voltages would be normal because the Stator is doing real work if it is plugged into the Regulator. But be on the lookout for seriously low output voltage on any phase of the Stator. A bad Regulator may collapse the Stator AC output on any or all phases. One low or high phase measurement when the Regulator is plugged in, despite seeing uniform AC voltages on each phase of the Stator when the Regulator us disconnected, suggests a bad Regulator. With the Stator and the Regulator connected normally, check the DC output voltage of the Regulator with the Regulator connected bike. For reference, check battery voltage first and keep that number in mind. Then start the bike and check battery voltage while it is running. Whatever voltage you see at idle should increase somewhat as you increase engine RPM but should stop climbing once it gets into the 14.5V to 15V range. If, when you are at 1500 RPM (high idle), it is not at least equal to the battery voltage you measured when the engine was not running at all, something is wrong (perhaps a bad Regulator, but possibly a bad Battery). If DC voltage keeps climbing past 15V when you increase RPM, STOP THE TEST before you blow bulbs or worse on your bike. And get a new Regulator. Disconnect the DC output of the Regulator from the bike and check Regulator output voltage while the bike is running, again slowly increasing RPM, checking to see how much output voltage increases as engine speed increases. If it is too low to charge your battery (say, less than 12.6V DC) or too high (say over 15V DC), you have a Regulator problem. |

Categories

All

Archives

January 2024

|

|

© WrenchMonster 2018

|

WrenchMonster™ is a Division of DemonLite, LLC.

|

RSS Feed

RSS Feed